Renewable Energy and Additive Manufacturing: Revolutionizing Production

As Europe continues its ambitious journey towards a green energy future, the intersection of renewable energy and additive manufacturing is poised to play a pivotal role in transforming the landscape. Additive manufacturing, also known as 3D printing, has emerged as a disruptive technology that is revolutionizing the way we approach energy production and component fabrication.

Emerging Technologies

The development of carbon-neutral sources, such as wind, solar, geothermal, hydroelectric, and nuclear power, marks a significant stride towards Europe’s renewable energy goals. These sustainable alternatives to traditional fossil fuels not only mitigate the effects of climate change but also offer a path towards energy security and independence.

Additive manufacturing has a transformative impact on the production of components for renewable energy systems. As a manufacturing process, it is inherently sustainable, minimizing waste by using only the necessary material, layer by layer, to create complex structures. This approach contrasts with traditional subtractive manufacturing, where the recovery of unused material is not an immediate process.

Sustainability Challenges

One of the primary advantages of additive manufacturing in the energy sector is its ability to produce cost-effective and highly efficient components that are crucial for the adoption and performance of renewable energy technologies. Many of these intricate parts, such as turbine blades for wind turbines or detailed components for solar panels, have historically been challenging and expensive to manufacture using conventional methods.

However, the sustainability of additive manufacturing extends beyond just the manufacturing process. It enables on-demand production, reducing the need for large inventories and long supply chains, further enhancing its environmental benefits.

Policy and Regulations

Recognizing the transformative potential of additive manufacturing in the energy sector, policymakers across Europe have implemented a range of initiatives and regulations to encourage its adoption. These efforts include tax incentives, research and development funding, and the development of industry standards and certification processes.

The European Commission’s Green Deal and Fit for 55 package have been instrumental in driving the transition towards a sustainable energy future, with ambitious targets for renewable energy deployment and emissions reduction. Additive manufacturing is positioned as a key enabler in achieving these goals, as it can help reduce the costs and lead times associated with the production of renewable energy components.

Additive Manufacturing

3D Printing Innovations

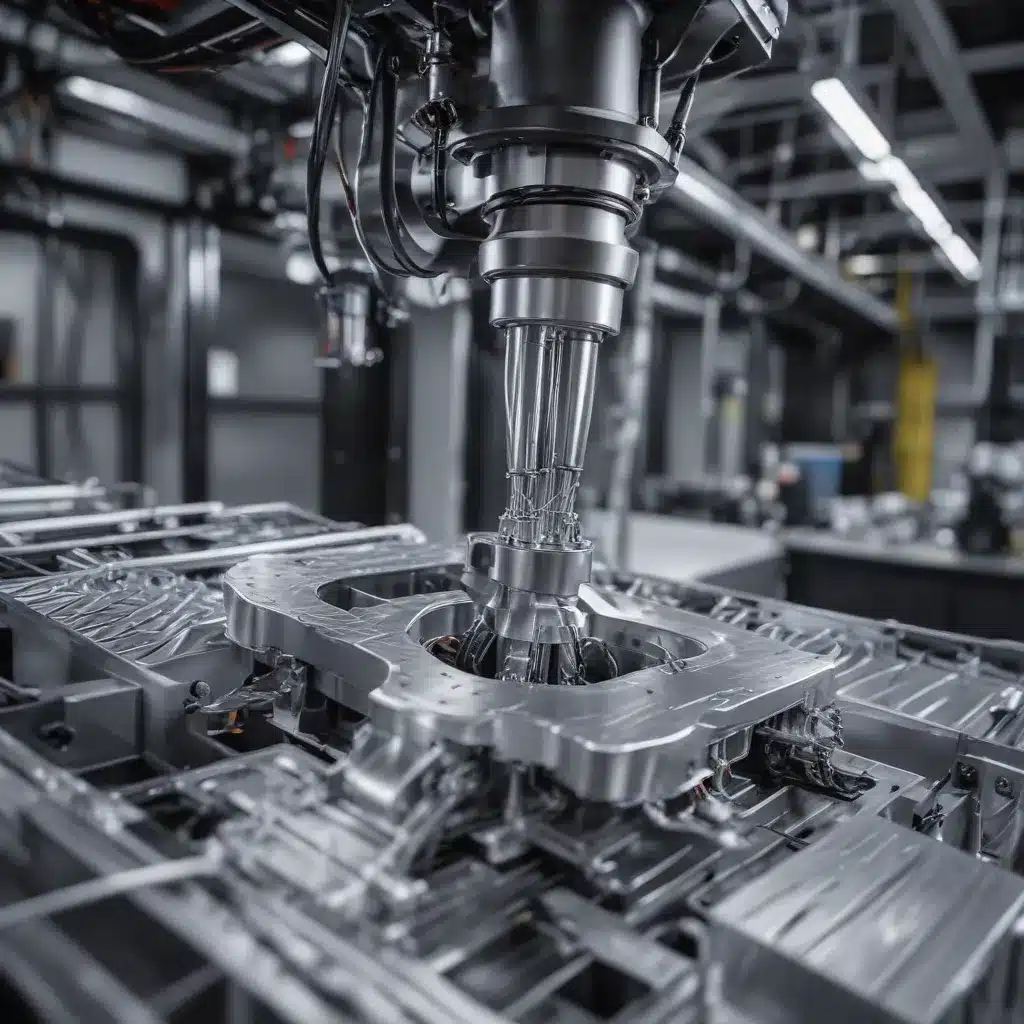

Additive manufacturing technologies, such as powder bed fusion and directed energy deposition, are redefining how components for energy production can be created and maintained. These advanced processes offer significant advantages over traditional manufacturing methods, enabling faster production times, greater design flexibility, and the fabrication of more durable and efficient components.

One of the most promising applications of additive manufacturing in the energy field is the repair and maintenance of structural components. The ability to reuse and refurbish worn parts, rather than manufacturing new ones, can result in substantial resource savings, cost reductions, and a more circular economy.

Material Science Advancements

The development of advanced materials, such as high-strength, lightweight alloys, has further enhanced the capabilities of additive manufacturing in the energy sector. These specialized materials, tailored for specific applications, can improve the performance and efficiency of renewable energy systems, contributing to their widespread adoption.

Scalability and Cost Considerations

As additive manufacturing technologies continue to evolve, the ability to scale up production and reduce manufacturing costs has become increasingly important. Innovations in large-scale 3D printing, robotic automation, and smart manufacturing techniques are paving the way for the mass production of renewable energy components, making them more accessible and economically viable.

Intersection of Renewable Energy and Additive Manufacturing

Production Efficiency

The integration of additive manufacturing into the renewable energy supply chain has the potential to revolutionize production efficiency. By enabling the on-demand fabrication of complex parts, additive manufacturing can significantly reduce lead times, inventory costs, and the reliance on long supply chains.

Supply Chain Optimization

Additive manufacturing also plays a crucial role in optimizing the supply chain for renewable energy components. By allowing for local, on-site production, it can minimize the environmental impact associated with the transportation of materials and finished products, while also enhancing the resilience of the supply chain.

Environmental Impact

The sustainability benefits of additive manufacturing extend beyond the manufacturing process itself. By enabling the repair and reuse of high-value components, it contributes to a more circular economy, reducing waste and the environmental impact of the energy sector.

Future Prospects

Industry Collaboration

The widespread adoption of additive manufacturing in the renewable energy sector will require close collaboration between industry stakeholders, policymakers, and research institutions. This partnership will be essential in driving technological advancements, developing industry standards, and overcoming any regulatory or market barriers.

Research and Development

Continued investment in research and development will be crucial in unlocking the full potential of additive manufacturing for renewable energy applications. Advancements in material science, process optimization, and scalable production techniques will further enhance the competitiveness and capabilities of this transformative technology.

Adoption Barriers

While the benefits of additive manufacturing in the renewable energy sector are compelling, there are still some barriers to widespread adoption. These include the need for specialized expertise, the initial capital investment required, and the integration of additive manufacturing workflows into established manufacturing processes. Overcoming these challenges will be a key focus for the industry in the years to come.

As Europe continues its transition towards a sustainable energy future, the synergy between renewable energy and additive manufacturing holds immense promise. By harnessing the capabilities of this disruptive technology, the energy sector can not only improve production efficiency and supply chain resilience but also contribute to a more environmentally conscious and economically viable model of energy generation. The future of renewable energy production is being shaped by the transformative power of additive manufacturing, and the European Future Energy Forum is at the forefront of this exciting revolution.